The use of renewable raw materials is more urgent than ever. With its new pilot plant, the Technical University of Dresden is researching how innovative recyclable materials can be sustainably produced from residual products from the agriculture, and forestry industry or grasses. The TU Dresden commissioned Thermische Apparate Freiberg GmbH (TAF) – a company of the Pörner Group – to plan and build the pilot plant for the thermal processing of biomasses.

In order to counteract the dependency on oil, gas and coal, the economy is looking for environmentally friendly solutions. The development of alternative processes and new products with the lowest possible CO2 footprint requires state-of-the-art research facilities with the highest precision and great flexibility.

For this reason, the European Regional Development Fund (ERDF) and the state of Saxony funded a new pilot plant for the digestion of various biomasses at the Institute for Plant and Wood Chemistry at the TU Dresden. Research focuses on the production of cellulose for the paper, textile and chemical industries, delignified wood, and veneers for functional materials, and other innovative products from agricultural residues (e.g. straw, hemp and flax), the wood and forestry industry (e.g. damaged wood, sawdust, and bark) and fast-growing plants (e.g. miscanthus / Chinese reed) in focus.

For this reason, the Institute for Plant and Wood Chemistry at the TU Dresden invested in a new pilot plant for the thermal processing of various biomasses. Research focuses on the production of cellulose, bioethanol and other innovative products from agricultural residues (e.g. straw, hemp and flax), the wood and forestry industry (e.g. damaged wood, sawdust, and bark) and fast-growing plants (e.g. miscanthus / Chinese reed).

In addition to the classic use of cellulose for the paper and packaging material production, the diverse application potential of cellulose, hemicellulose, and lignin to replace fossil raw materials in various branches of industry are of growing interest.

Utilization of straw & co.

The Thermische Apparate Freiberg (TAF), a company of the plant engineering provider Pörner Ingenieurgesellschaft mbH in Vienna / Austria, received the order from the Institute for Plant and Wood Chemistry at the TU Dresden for the overall implementation of the pilot plant for the thermal processing of various biomasses. The order includes the new conception, design, engineering, construction, assembly and commissioning of the plant. The grant of 1.115 million euros comes from the European Regional Development Fund (ERDF) and tax revenues and contributes to improving the infrastructure in application-oriented research.

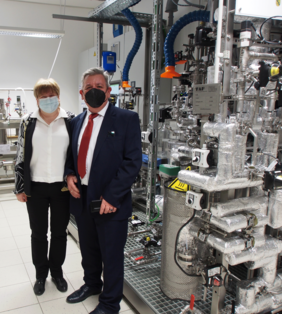

After successful test operation and personnel training, TAF handed over the plant, also known as the "cellulose digester system", to the institute at the end of February. On March 9, 2022, the Saxon State Minister for Regional Development, Thomas Schmidt, attended the inauguration.

The plant on a research-relevant scale is currently almost unique in Central Europe. The institute therefore sees excellent opportunities for intensive cooperation with other research institutions and various industrial sectors within the framework of funded projects. The state-of-the-art and fully equipped pilot plant enables the research and verification of alternative processes, the adjustment of essential parameters such as time, temperature or pH, and the minimization of energy and chemical use.

Thermal solution from Freiberg, Saxony

The plant consists of two electrically heated reactors with a reactor volume of 30 and 8 liters, respectively. It can be operated with parameters up to 200 °C both at atmospheric pressure and up to 20 bar. On a 20 to 25-liter scale, renewable raw materials and residues can be pyrolyzed using a wide variety of processes. The new replaces the old plant in the technical center of the institute in Tharandt.

TAF has developed into a specialist in the construction of research plants over the past decade and is able to design and fully equip compact, fully instrumented and automated research and pilot plants in-house, precisely according to the requirements of the researchers, to then put them into operation on site together with the customer. For example, only in 2021, TAF delivered a research plant to recycle phosphorus from sewage sludge to RWE.

Jonas Kappeller, Managing Director of TAF: "We are proud to set an important sign here. The new pilot plant will lead companies to major research progresses in utilizing renewable raw materials. Despite an adverse procurement situation, we were able to complete the project on time and are pleased to have found a practical solution for every wish of the TU research team."

Alternative pyrolysis methods are in the starting blocks

The pilot plant was dedicated to its purpose of making many valuable contributions to practical and sustainable products in the future. It enables research on an entirely new level. The path from research to the implementation of the technology to bio-based value chains is ready to be walked. The demand for biofuels and green products is high. However, to implement sustainable production facilities on a large scale, the federal government still has to create the necessary framework conditions.

TAF:

Thermische Apparate Freiberg (TAF) is specialist in the design and construction of process equipment for gasification technologies and is a developer and supplier of special solutions in mechanical and plant engineering. Compact, fully instrumented and automated research and pilot plants are designed, fully equipped and manufactured in-house according to the requirements of the researchers. TAF was founded in 1997 and has been a member of the Pörner Group since 2014.

More information here: https://www.taf-freiberg.com/