Formaldehyde & Derivatives

Your Technology Center for Formaldehyde and Derivatives

Within the Pörner Group, Pörner Grimma is the technology center dedicated to formaldehyde and its derivatives. Our experienced team has successfully completed around 25 projects in this product group, demonstrating our competence, reliability, and commitment to continuous innovation.

Technology Center with Expertise

Our portfolio includes the sales, engineering, and construction of complete production plants within the formaldehyde technology family. In close cooperation with renowned European licensors and know-how partners, Pörner Grimma provides comprehensive EPCM (engineering, procurement, and construction management) solutions.

We design and provide the core production units, as well as all the necessary auxiliary, utility, and infrastructure units, ensuring seamless and efficient operation of the plant.

Our expertise includes:

- FORMALDEHYDE production based on Silver Catalyst and Metal Oxide Catalyst

- UFC (Urea formaldehyde precondensate) production based on Silver Catalyst and Metal Oxide Catalyst

- HEXAMINE (Hexamethylenetetramine) production, Liquid Phase and Gaseous Phase Process

- GLUES and RESINS (UF, MF, MUF, PF, Epoxy, Alkyd, Polyester, Novolaks, Powder Bakelite) production

Learn more about our projects and services. Put your trust in our company's long-standing expertise and ability to rise to the industry's challenges.

Technology Overview

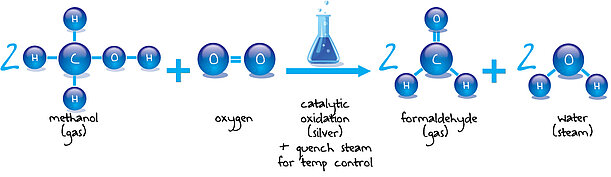

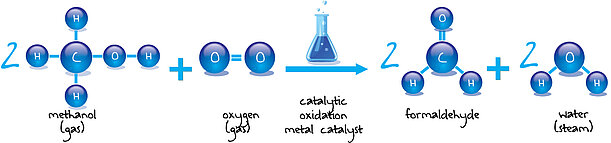

Technically, formaldehyde can be produced using the catalytic oxidation of methanol. There are two methods: Silver Catalyst and Metal Oxide Catalyst process.

The Silver Catalyst Process

- A mixture of evaporated methanol and ambient air is fed to the silver catalyst. The generated process gas is then absorbed in water and condensed in a selective absorption step.

- Standard solutions of up to 49 % w/w formaldehyde and 1-2 % w/w methanol can be produced without distillation.

- Alternatively, we offer special tail gas recycling technology to produce highly concentrated formaldehyde solutions of up to 55 % w/w formaldehyde and 0.5-1 % w/w methanol without distillation.

- The H₂-rich absorption tail gas is combusted in a thermal oxidizer or special boiler, generating steam, which can be fed to a gas motor to generate electric power.

Replacing the catalyst takes just a few hours and does not generate any dust or waste. Refilling the catalyst takes less than 24 hours, meaning small holding tanks can supply consumers during refilling.

The Metal Oxide Catalyst Process

- Vaporous methanol and ambient air are fed to a metal oxide catalyst (iron oxide combined with molybdenum and/or vanadium).

- The generated process gas is then absorbed in water and condensed in an absorption step.

- Approximately one third of the absorbed gas is recycled to the reactor. Formaldehyde solutions containing up to 55 % w/w formaldehyde and 0.5-1 % w/w methanol are produced.

- The off-gas from the absorption step is oxidized on a palladium catalyst, which can be equipped with waste heat recovery.

Formaldehyde is a key raw material for the chemical industry. More than 50 industrial sectors rely on formaldehyde and its derivatives, which have countless applications in industry and everyday life, including adhesives and resins.

Pörner Grimma specializes in formaldehyde production processes and the downstream technologies that convert formaldehyde into its many derivatives. Our plants provide the basis for the production of versatile goods used worldwide in the construction, automotive, furniture, textile, and household industries.

We design and supply plants for the following product groups:

- Formaldehyde

- Urea-formaldehyde precondensate (UFC)

- Hexamethylenetetramine (hexamine, urotropine)

- Urea-formaldehyde (UF)

- Melamine-formaldehyde (MF)

- Melamine-urea-formaldehyde (MUF)

- Phenol-formaldehyde (PF) resins

- Epoxy resins

- Alkyd and polyester resins

- Adhesives and glues

- Novolac and Resol products

- Powder Bakelite

The Silver Catalyst Process is considered the safest method of producing formaldehyde. Due to its lower formic acid content and the elimination of caustic soda and anti-foaming agents, the resulting product enables broader downstream processing. The process uses only water and steam, eliminating the need for heat transfer oil and oxygen in the absorber. This enhances product quality while reducing fire risks.

The Metal Oxide Catalyst Process produces a higher yield of formaldehyde while reducing methanol consumption. Investment costs are comparable to those of the silver catalyst process, making the metal oxide catalyst process a robust alternative in many markets.

Although the investment costs for the silver and metal oxide catalyst processes are similar, the silver catalyst process offers three key advantages:

- The catalyst is cheaper because it is fully regenerable

- Energy consumption is lower

- Greater efficiency due to higher steam generation and lower cooling requirements

These advantages outweigh the slightly higher methanol consumption compared to the metal oxide catalyst process.

„Together with our licensing partner, we have developed plants that use the silver catalyst process into the best of their kind. Technical and economic comparisons by several international customers, as well as experience gained from the joint planning and construction of more than 25 plants in recent years, prove this.“

Gerhard Bacher, Geschäftsführer Pörner Grimma

Pörner allows you to freely choose your catalyst supplier. The process decision is ultimately determined by the individual wishes and needs of our customers. The main factors here are the costs for raw materials, catalysts, consumables, and operating resources, as well as aspects relating to operational procedures and safety.

Gerhard Bacher

Managing Director Pörner Grimma

Pörner Ingenieurgesellschaft Germany

Leipziger Straße 52, 04668 Grimma, Germany

Phone: +49 3437 9854 - 0

Email: g.bacher@poerner.de