synthetic waxes and their making

SynWax™

SynWax™ is a controlled de-polymerization process to convert polyolefins into high-value specialty wax grades.

Commercial & Strategic Value

SynWaxTM offers excellent cost effectiveness by converting commodity, transition, and recycled materials into high-value specialty products using a compact and proven process.

The technology is supported by a reference plant in operation since 2017, established application know-how, and full lab and QA capabilities.

SynWaxTM enables polyolefin producers and industrial partners to expand into specialty wax markets, strengthen customer relationships through application-driven solutions, and unlock circular value creation pathways.

The technology and application know-how are available under license.

Technology Overview

SynWax™ is based on polyethylene (PE) and polypropylene (PP) feedstock.

Depending on the targeted product family, the technology can process:

- Virgin PE and PP, including green polyolefin grades

- Quality-controlled off-spec and transition materials

- Selected recycled polyolefins

This flexible feedstock concept allows the production of premium specialty waxes as well as technical wax grades and circularity-driven products such as "SynWax2Bitumen".

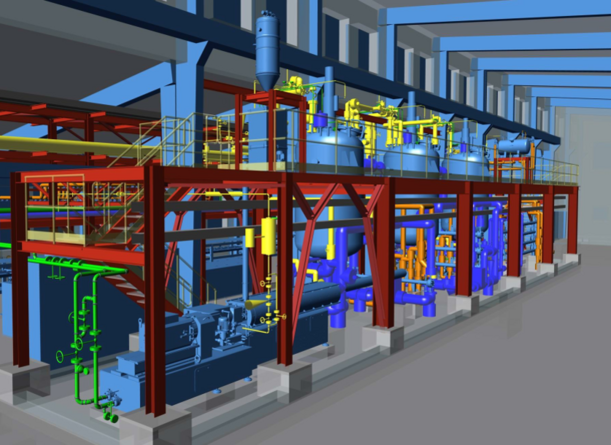

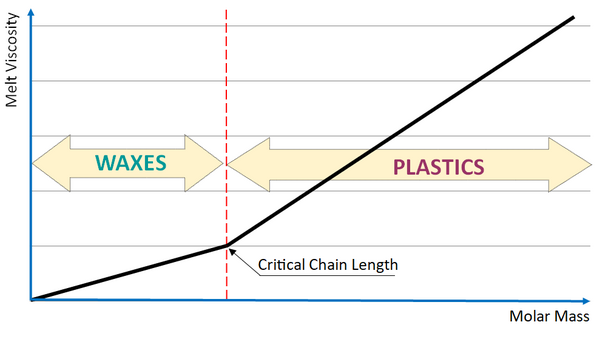

SynWax™ is based on a controlled thermal de-polymerization process.

Polyolefin feedstock is melted and converted under defined temperature and residence time conditions, allowing precise adjustment of molecular chain length into the wax range.

Key process characteristics include:

- Controlled chain-length reduction for tailored wax properties

- Nitrogen blanketing and degassing for stable and safe operation

- Modular, scalable plant design with multiple reactor stages

- Pastillation or configuration for defined solid product forms

The compact and proven process design ensures consistent product quality and industrial scalability.

SynWax™ enables the production of fully synthetic polyolefin-based waxes with engineered property profiles.

Product characteristics include:

- Adjustable melting and softening behavior

- Controllable viscosity as a key processing lever

- Hydrophobic and chemically stable performance

- Non-polar and polar (oxidized) wax variants

The product portfolio is structured into three main families:

- Class A: Premium waxes from virgin polyolefins for high-performance applications

- Class B: Technical waxes from off-spec / transition materials or selected recycled feedstock

- Class C: “SynWax2Bitumen” additives for asphalt and road construction – for temperature reduction during the complete road construction

SynWax™ offers clear technical, economic, and strategic advantages.

- Extension of the polyolefin value chain into specialty wax markets

- Tailor-made wax properties with high reproducibility

- Improved processing performance in plastics, adhesives, and coatings

- Economical production using commodity and recycled feedstock

- Proven industrial reference with scalable plant concepts

- Technology that enables the upgrading of recycled material

A SynWax™ reference plant is operated at our technology partner Mitteldeutsches Paraffinwerk (MPW) in Saxony, Germany. Since 2017 in operation, the proven fully automated plant configuration including pastelizing, produces high purity products for leading German industrial customers.

Application expertise and product development

MPW R&D and lab capabilities for both for wax and bitumen enable the development of tailored special synthetic wax grades and pilot tests on different feed materials.

The facilities allow:

- Feedstock screening and qualification (virgin, off-spec, recycled PE/PP)

- Adjustment and validation of process parameters

- Production of representative wax samples for application testing

- Customer-specific grade development and benchmarking

The R&D capabilities bridge laboratory development and industrial scale, significantly increasing technical reliability and accelerating time-to-market for new SynWax™ product grades.